Explosion Proof 20 Tons Electric Trackless Transfer Cart

Description

This transfer c art is powered by a maintenance-free battery and is equipped with a portable charger that can be charged at any time to meet production needs. In addition, in order to ensure safe use, the cart is equipped with shock-absorbing buffers and a laser automatic stop device that can reduce collisions in sudden situations.

In addition, there is a standard emergency stop button on the electrical box, which the operator can press to instantly cut off the power of the transfer cart to reduce losses.

Different from the traditional driving method, the electric drive of the trackless transfer cart not only eliminates the emission of pollutants, but can also be controlled by wired handles or wireless remote controls, reducing the difficulty of use.

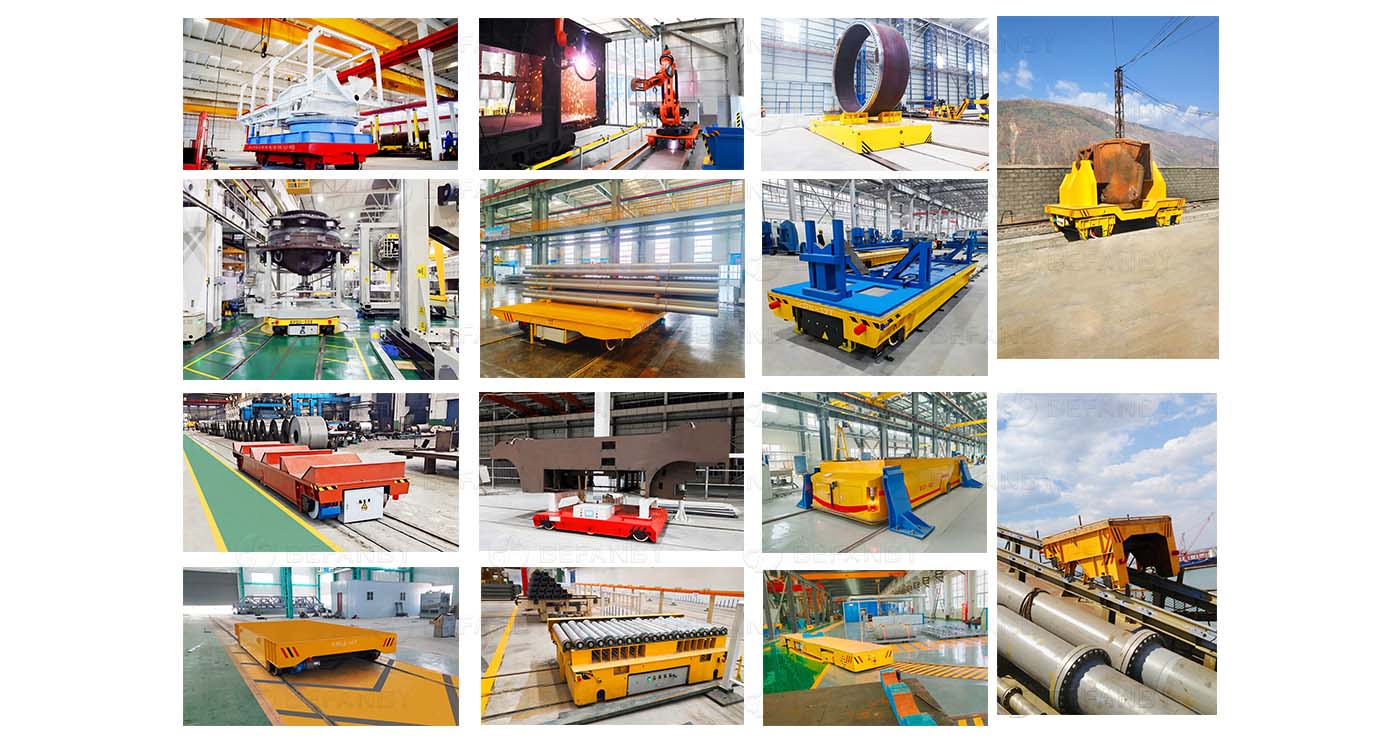

Site Case

"Explosion Proof 20 Tons Electric Trackless Transfer Cart" is used in production workshops to transport various materials. From the picture, we can see that this is a foundry with various building materials.

To protect the transfer cart from wear and tear when transporting building materials, some wooden strips are placed on the table to isolate the building materials and protect the transporter from damage.

Trackless transfer carts have the advantages of explosion-proof and high temperature resistance. In addition to being used in production workshops, they can also be widely used in harsh workplaces such as glass factories and foundries.

Strong Capacity

This trackless transfer cart has a maximum load capacity of 20 tons and a table size of 2500*2000*500 mm. The table is large enough to ensure the stability of materials during transportation and effectively prevent materials from slipping due to turning, etc. In addition, the transfer cart adopts a spliced structure frame, which is wear-resistant and durable.

Customized For You

Almost every product of the company is customized. We have a professional integrated team. From business to after-sales service, technicians will participate in the whole process to give opinions, consider the feasibility of the plan and keep following up on the subsequent product debugging tasks. Our technicians can make customized designs according to the specific needs of customers, from power supply mode, table size to load, table height, etc. to meet customer needs as much as possible, and strive for customer satisfaction.